What are the commonly used printing papers? Printing paper basics

After the invention of papermaking in 105 AD, papermaking was spread from Henan to other areas with developed economic and cultural properties. Cai Lun was sealed to Longting Hou in Yangxian, Shaanxi Province, and papermaking was transmitted to Hanzhong and gradually spread to Sichuan. In the processing and manufacturing technology, the lye cooking and crucible are strengthened, the quality of the paper is improved, and processed paper such as colored paper, filled paper, and filler paper appears.

1, offset paper (Dawlin paper)

The offset paper is divided into three types according to the ratio of paper pulp, No. 1 and No. 2, and there are two sides, one side and two sides, and two levels of super calendering and ordinary calendering. The paper weight is 50, 60, 70, 80, 90, 100, 120, 150, 180 (g / m2), of which the commonly used double-sided offset paper has 70, 80, 90, 100, 120 (g / m2), single Offset offset papers are available in 50, 60, 70, 80 (g/m2).

The offset paper has small stretchability, uniform absorption of ink, good smoothness, tight opacity texture, good whiteness and strong water resistance. Used for processing and manufacturing thin paper packaging and decoration printing. When the offset paper is printed, the paper should not be piled too high. In particular, the printing with high smoothness and large amount of ink should prevent the back side from being dirty. Generally, anti-dirty agent, dusting or lining paper is used. Conjunctival offset printing inks and good quality printing inks should be used. The viscosity of the ink should not be too high, otherwise powder removal and pulling will occur.

Flat paper specifications: 787 × 1092, 850 × 1168, 880 × 1225 (mm × mm).

Web specifications: 787, 1092, 850 (mm) width.

Uses: Offset paper main feed (offset) printing machine or other printing machine used to print higher-grade color prints, such as color pictorials, albums, posters, color printing trademarks and some advanced book covers, illustrations and so on.

2, coated paper

Coated paper, also known as coated paper, is a high-grade printing paper, which is also called printing coated paper, which is inserted into a white sheet on the base paper and processed by super calendering. The whiteness is high, the paper fibers are evenly distributed, the thickness is uniform, the stretchability is small, the elasticity is better, the water resistance and the tensile properties are replaced, and the absorption and receiving state of the ink are very good. The pressure on the coated paper should not be too large. To prevent the back from being dirty, it is possible to add anti-dirt and dusting methods.

Coated paper has two types, single and double. Weight: 70, 80, 100, 105, 115, 120, 128, 150, 157, 180, 200, 210, 240, 250 (g / m2); where: 105, 115, 128, 157 (g / m2) imports There are many paper specifications.

Flat paper specifications: 648 × 953, 787 × 970, 787 × 1092 (currently there is no web in China). 889×1194 is the specification of imported coated paper.

Coated paper is mainly used for printing albums, covers, postcards, exquisite product samples, and color labels.

3, white paper

White paper is a kind of outer packaging paper for printing various trademarks and packaging cartons, weighing 220,240,250,280,250,350,400 (g/m2); flat paper specifications: 787×787 , 787 × 1092, 1092 × 1092 (mm × mm).

White paper is composed of pulp and noodles, and the pulp is white. The pulp is generally the natural color of the raw materials. White paper is divided into two types according to the paper surface: white and white. According to the bottom layer, there are two kinds of gray bottom and white bottom. The quality requirements of white paper: white, smooth, uniform thickness, firm texture, no powder removal, uniform ink absorption, small expansion, toughness, no break when bending.

Mainly used for printing packaging boxes and goods decorative lining paper. In book binding, it is used for binding materials such as paper seals and ridges in hardcover books and hardcover books.

4, letter paper

Letterpress paper is the main paper used when letterpress printing books and magazines are used. The letterpress paper can be divided into four grades of No. 1, No. 2, No. 3 and No. 4 according to the distribution ratio of the paper materials. The number of papers represents the quality of the paper. The larger the number, the worse the paper quality. Paper weight: (49 ~ 60) ± 2 (g / m2); flat paper specifications: 787 × 1092, 850 × 1168, 880 × 1225 (mm × mm); web specifications: width 787, 1092, 1575 (mm There are also some special size papers.

Letterpress paper is mainly used for letterpress printing. The characteristics of this paper are similar to, but not identical to, newsprint. Since the ratio of paper pulp to pulp is better than that of newsprint, the fiber structure of the letterpress paper is relatively uniform, and the gap between the fibers is filled with a certain amount of filler and rubber, and is also bleached, which forms This paper has a good adaptability to printing. It is slightly different from newsprint. Although its ink absorption is not as good as newsprint, it has the characteristics of uniform ink absorption; water resistance and paper whiteness are better than newsprint.

The relief paper has uniform texture, no lint, slight elasticity, opacity, slight water resistance, and certain mechanical strength.

Applicable to important works, scientific books, academic journals, textbooks for colleges and universities, etc.

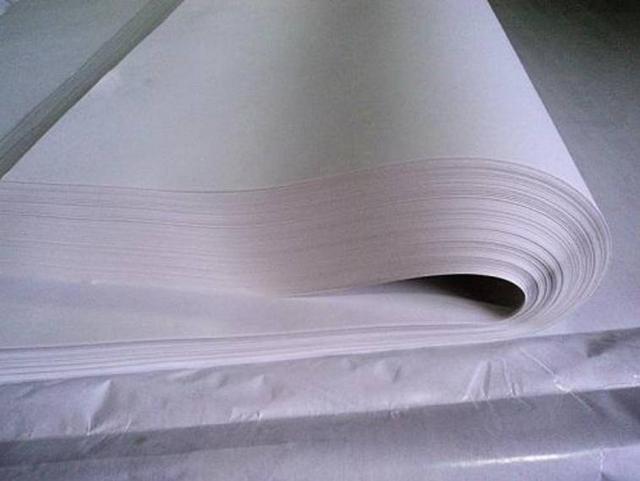

5, news paper

Newsprint is also called white paper, which is the main paper for newspapers and books. The characteristics of newsprint are: paper is light and light, with good elasticity; good ink absorption performance, which ensures that the ink can be fixed on the paper surface; after the paper is calendered, both sides are smooth and no hair, so that the two sides The print is clear and full; has a certain mechanical strength; good opacity; suitable for high speed rotary printing. Its weight is: (49 ~ 52) ± 2 (g / m2), flat paper specifications: 787 × 1092, 850 × 1168, 880 × 1225 (mm × mm), web specifications: width 787, 1092, 1575 ( Mm).

This paper is made from mechanical wood pulp (or other chemical pulp) and contains a lot of lignin and other magazines. It should not be stored for a long time. If the storage time is too long, the paper will become yellow and brittle, and the water resistance is poor. It is not suitable for writing. Printing ink or book ink must be used, the viscosity of the ink should not be too high, and the moisture of the layout must be strictly controlled during lithography.

Applicable to newspapers, periodicals, textbooks, comic strips and other text papers.

6, embossed paper

Embossed paper is a kind of cover decorative paper specially produced. The surface of the paper has a pattern that is not very noticeable. The colors are gray, green, beige and pink, and are generally used to print monochrome covers. The embossed paper is brittle and the spine is easily broken when bound. The paper has a large degree of curvature during printing, and paper feeding is difficult, which affects printing efficiency.

7, dictionary paper

Dictionary paper is a kind of high-grade thin book paper. The paper is thin and strong and resistant. The paper surface is white and fine, the texture is tight and smooth, slightly transparent, and has certain water resistance. Mainly used for printing dictionaries, dictionaries, manuals, classic books and pages with more pages and easy to carry. Dictionary paper has high requirements on the pressure and ink color in the printing process, so the process must pay special attention to the process.

8, kraft paper

Kraft paper has a high tensile force, such as single light, double light, stripes, no grain, and the like. Mainly used for wrapping paper, envelopes, paper bags, etc. and printing machine drum lining.